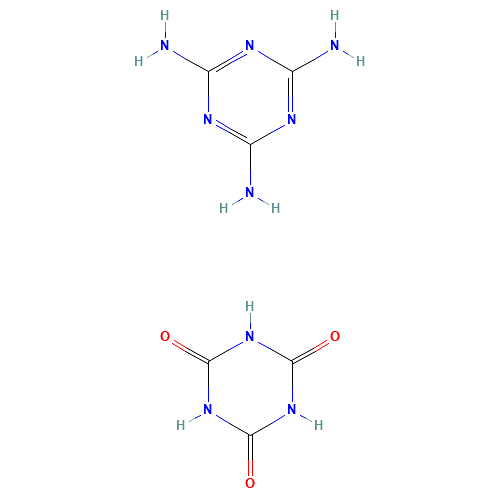

Melamine Cyanurate

멜라민 시아누레이트

1,3,5-Triazine-2,4,6(1H,3H,5H)-trione compd. with 1,3,5-triazine-2,4,6-triamine (1:1)

CAS RN : 37640-57-6

화학식 : C6H9N9O3

분자량 : 255.2

속성:

멜라민 시아 누 레이트 (MCA)는 할로겐 프리 난연제로 특히 폴리 아미드 (PA6, PA66)에 사용됩니다.

MCA는 전선 및 케이블, 전자 제품, 건축 자재, 섬유 코팅에 널리 사용됩니다.

기능:

- 환경, 할로겐 프리.

- 전기적 및 기계적 특성.

- 꾸준한 색깔.

Phosphate Flame Retardants (FRs):

>>Halogen-free Aromatic PolyPhosphate FRs:

RDP BDP

For Engineering plastics (e.g. PC/ABS alloys, PC, ABS, modified PPE), etc.

>>Halogenated Chlorinated Phosphate FRs:

TCPP TDCPP

For Polyurethanes (e.g. flexible and rigid PUR foams), etc.

>>Melamine-based nitrogen-phosphorus FRs:

Melamine Phosphate -MP

Melamine PolyPhosphate -MPP

The following is the original English text. |

다음 은 영어 본문 이다.

Melamine Cyanurate

CAS Number: 37640-57-6

Chemical formula: C6H9N9O3

Molecular weight: 255.2

Melamine Cyanurate(MCA) is a halogen-free flame retardant, especially used for unfilled polyamide (PA6, PA66).

Uses:

MCA are widely used in rubber, nylon (polyamide), phenolic resin, polystyrene, epoxy resin, acrylic emulsion, PTFE resin and other olefin resin.

MCA can be applied to materials and parts with high requirements for flame retardant insulation grade, wire and cable, electronic appliances, building materials, textile coatings.

MCA can be used as a lubricant with better lubricating properties than molybdenum disulfide, but it is cost-effective. MCA’s coating film can be used as a lubricant film for rust prevention, as a release agent for steel drawing and stamping, and as a lubricant film for general mechanical transmission parts.

MCA has non-toxicity, good lubricity, can be formulated for skin cosmetics, and can also be used as paint matting agent.

Features:

1. Environmental, halogen-free.

2. Good electrical and mechanical property.

3. Steady color.

Technical Data:

| Appearance | White Powder |

| MCA content [%] | 99.5 min. |

| Cyanuric acid [%] | 0.2 max. |

| Loss on dry [%] | 0.2 max. |

| Average particle size [μm] | 5.0 max. |

Flame retardant mechanisms:

1, MCA flame retardant reaches 350 degrees, began to decompose to generate MA and CA, this process needs to absorb a large amount of heat from the polymer to reduce the surface temperature of the substrate.

2, CA and MA further decomposition to generate non-combustible gases, such as ammonia, etc., these non-flammable gases can quickly dilute the polymer generated combustibles and oxygen, reducing the concentration of combustible gases.

3, MCA generally needs to be compounded with phosphorus-containing or pentaerythritol, etc., which will promote the foaming and expansion of the carbonised layer, and can prevent the convection of heat and outside oxygen.

4, Non-combustible drips to minimize contact with flames.